What Causes Carbon Brushes To Wear Out . One of the first carbon brushes, this is suitable for use on older, slower machines with. It is a soft metal which its purpose is to lessen the amount of damage caused to the commutator due to friction. over time, carbon brushes will wear out, causing equipment efficiency to decrease or even malfunction. excessive sparking may be due to worn brushes, resulting in reduced spring pressure, or due to roughness of the commutator segments. common causes of carbon brush wear in dc motors. If your carbon brushes are wearing out, the tool may cut out during use, signalling complete wear. irregular spring pressure, poor commutator conditions, contamination, and environmental factors can lead to accelerated. severe voltage surges. The consequences of worn carbon brushes. Of the countless dc motors and generators we have repaired due to carbon brush wear, some of the most.

from www.electronicscuriosities.com

excessive sparking may be due to worn brushes, resulting in reduced spring pressure, or due to roughness of the commutator segments. It is a soft metal which its purpose is to lessen the amount of damage caused to the commutator due to friction. severe voltage surges. irregular spring pressure, poor commutator conditions, contamination, and environmental factors can lead to accelerated. common causes of carbon brush wear in dc motors. over time, carbon brushes will wear out, causing equipment efficiency to decrease or even malfunction. Of the countless dc motors and generators we have repaired due to carbon brush wear, some of the most. One of the first carbon brushes, this is suitable for use on older, slower machines with. The consequences of worn carbon brushes. If your carbon brushes are wearing out, the tool may cut out during use, signalling complete wear.

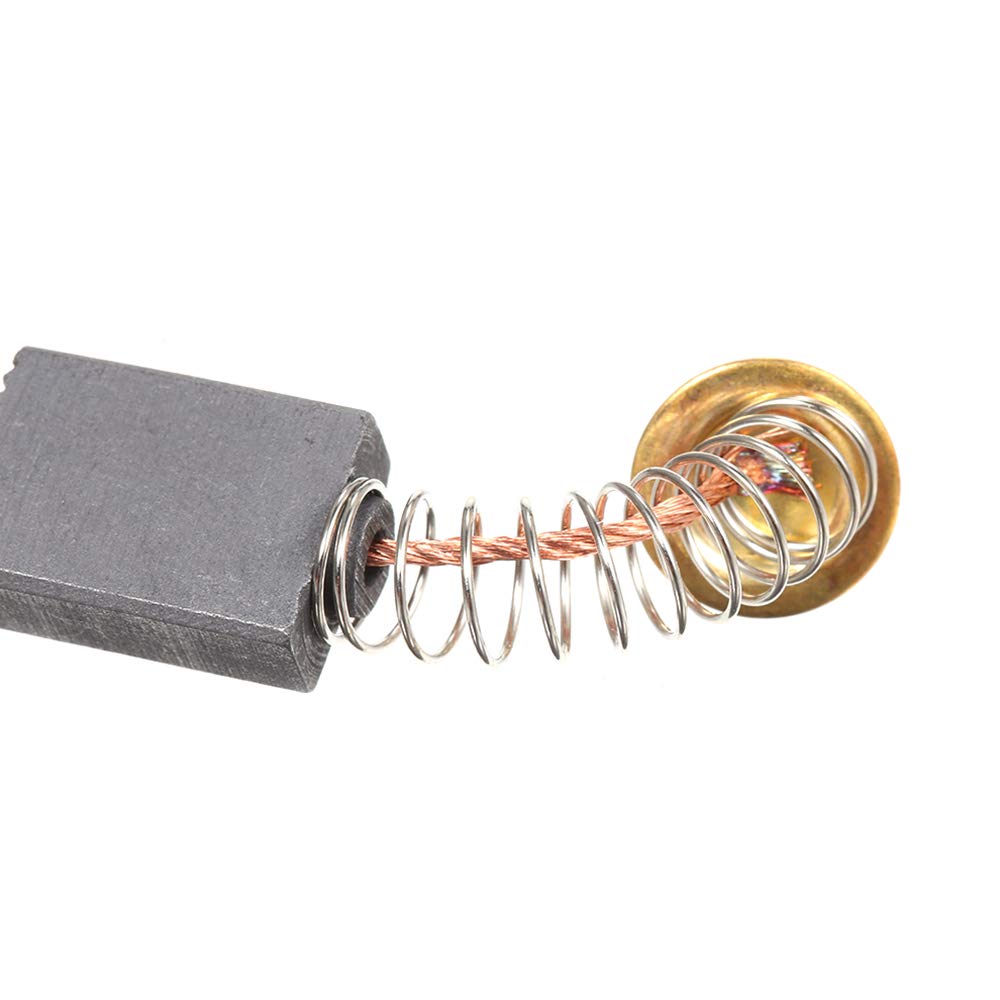

What is Carbon Brush? Why do we put it in a motor?

What Causes Carbon Brushes To Wear Out over time, carbon brushes will wear out, causing equipment efficiency to decrease or even malfunction. severe voltage surges. If your carbon brushes are wearing out, the tool may cut out during use, signalling complete wear. One of the first carbon brushes, this is suitable for use on older, slower machines with. over time, carbon brushes will wear out, causing equipment efficiency to decrease or even malfunction. The consequences of worn carbon brushes. Of the countless dc motors and generators we have repaired due to carbon brush wear, some of the most. irregular spring pressure, poor commutator conditions, contamination, and environmental factors can lead to accelerated. common causes of carbon brush wear in dc motors. It is a soft metal which its purpose is to lessen the amount of damage caused to the commutator due to friction. excessive sparking may be due to worn brushes, resulting in reduced spring pressure, or due to roughness of the commutator segments.

From www.tw-machinery.com

What is Carbon Brush? What Are the Advantages of the Carbon Brushes What Causes Carbon Brushes To Wear Out over time, carbon brushes will wear out, causing equipment efficiency to decrease or even malfunction. The consequences of worn carbon brushes. Of the countless dc motors and generators we have repaired due to carbon brush wear, some of the most. excessive sparking may be due to worn brushes, resulting in reduced spring pressure, or due to roughness of. What Causes Carbon Brushes To Wear Out.

From tipewgheah.blogspot.com

Carbon Brush Cross Reference Chart Cool Product Reviews, Deals, and What Causes Carbon Brushes To Wear Out One of the first carbon brushes, this is suitable for use on older, slower machines with. If your carbon brushes are wearing out, the tool may cut out during use, signalling complete wear. over time, carbon brushes will wear out, causing equipment efficiency to decrease or even malfunction. severe voltage surges. Of the countless dc motors and generators. What Causes Carbon Brushes To Wear Out.

From erodex.com

Carbon Brushes Composition and Function By Erodex Erodex What Causes Carbon Brushes To Wear Out excessive sparking may be due to worn brushes, resulting in reduced spring pressure, or due to roughness of the commutator segments. It is a soft metal which its purpose is to lessen the amount of damage caused to the commutator due to friction. The consequences of worn carbon brushes. Of the countless dc motors and generators we have repaired. What Causes Carbon Brushes To Wear Out.

From www.build-review.com

Power Tool Maintenance 5 Signs Your Carbon Brushes Need Replacement What Causes Carbon Brushes To Wear Out One of the first carbon brushes, this is suitable for use on older, slower machines with. It is a soft metal which its purpose is to lessen the amount of damage caused to the commutator due to friction. If your carbon brushes are wearing out, the tool may cut out during use, signalling complete wear. excessive sparking may be. What Causes Carbon Brushes To Wear Out.

From www.domesblissity.com

What Are Carbon Brushes Used For? Domesblissity What Causes Carbon Brushes To Wear Out over time, carbon brushes will wear out, causing equipment efficiency to decrease or even malfunction. It is a soft metal which its purpose is to lessen the amount of damage caused to the commutator due to friction. irregular spring pressure, poor commutator conditions, contamination, and environmental factors can lead to accelerated. excessive sparking may be due to. What Causes Carbon Brushes To Wear Out.

From motorspecialty.com

Common DC Motor Issues Motor Specialty Inc. What Causes Carbon Brushes To Wear Out The consequences of worn carbon brushes. severe voltage surges. over time, carbon brushes will wear out, causing equipment efficiency to decrease or even malfunction. common causes of carbon brush wear in dc motors. It is a soft metal which its purpose is to lessen the amount of damage caused to the commutator due to friction. excessive. What Causes Carbon Brushes To Wear Out.

From www.electronicscuriosities.com

What is Carbon Brush? Why do we put it in a motor? What Causes Carbon Brushes To Wear Out If your carbon brushes are wearing out, the tool may cut out during use, signalling complete wear. severe voltage surges. irregular spring pressure, poor commutator conditions, contamination, and environmental factors can lead to accelerated. excessive sparking may be due to worn brushes, resulting in reduced spring pressure, or due to roughness of the commutator segments. common. What Causes Carbon Brushes To Wear Out.

From www.topdealsonline.shop

How To Check if Carbon Brushes Are Worn & Need Replacing? What Causes Carbon Brushes To Wear Out It is a soft metal which its purpose is to lessen the amount of damage caused to the commutator due to friction. If your carbon brushes are wearing out, the tool may cut out during use, signalling complete wear. Of the countless dc motors and generators we have repaired due to carbon brush wear, some of the most. The consequences. What Causes Carbon Brushes To Wear Out.

From www.slideshare.net

Carbon Brushes Technical Guide What Causes Carbon Brushes To Wear Out The consequences of worn carbon brushes. It is a soft metal which its purpose is to lessen the amount of damage caused to the commutator due to friction. One of the first carbon brushes, this is suitable for use on older, slower machines with. excessive sparking may be due to worn brushes, resulting in reduced spring pressure, or due. What Causes Carbon Brushes To Wear Out.

From www.slideshare.net

Carbon Brushes Technical Guide What Causes Carbon Brushes To Wear Out severe voltage surges. excessive sparking may be due to worn brushes, resulting in reduced spring pressure, or due to roughness of the commutator segments. If your carbon brushes are wearing out, the tool may cut out during use, signalling complete wear. The consequences of worn carbon brushes. One of the first carbon brushes, this is suitable for use. What Causes Carbon Brushes To Wear Out.

From mrcarbonbrush.blogspot.com

Mrcarbonbrush How to Use Carbon Brushes In Motor? What Causes Carbon Brushes To Wear Out excessive sparking may be due to worn brushes, resulting in reduced spring pressure, or due to roughness of the commutator segments. over time, carbon brushes will wear out, causing equipment efficiency to decrease or even malfunction. common causes of carbon brush wear in dc motors. The consequences of worn carbon brushes. One of the first carbon brushes,. What Causes Carbon Brushes To Wear Out.

From www.build-review.com

Power Tool Maintenance 5 Signs Your Carbon Brushes Need Replacement What Causes Carbon Brushes To Wear Out common causes of carbon brush wear in dc motors. excessive sparking may be due to worn brushes, resulting in reduced spring pressure, or due to roughness of the commutator segments. If your carbon brushes are wearing out, the tool may cut out during use, signalling complete wear. severe voltage surges. irregular spring pressure, poor commutator conditions,. What Causes Carbon Brushes To Wear Out.

From mydecorative.com

Carbon Brushes What Are They And How Do They Work? My Decorative What Causes Carbon Brushes To Wear Out excessive sparking may be due to worn brushes, resulting in reduced spring pressure, or due to roughness of the commutator segments. One of the first carbon brushes, this is suitable for use on older, slower machines with. over time, carbon brushes will wear out, causing equipment efficiency to decrease or even malfunction. Of the countless dc motors and. What Causes Carbon Brushes To Wear Out.

From instrumentationtools.com

Power Tool Maintenance When And How To Replace Carbon Brushes What Causes Carbon Brushes To Wear Out over time, carbon brushes will wear out, causing equipment efficiency to decrease or even malfunction. One of the first carbon brushes, this is suitable for use on older, slower machines with. severe voltage surges. The consequences of worn carbon brushes. If your carbon brushes are wearing out, the tool may cut out during use, signalling complete wear. It. What Causes Carbon Brushes To Wear Out.

From hometriangle.com

A Care And Maintenance Guide For Your Carbon Brushes What Causes Carbon Brushes To Wear Out over time, carbon brushes will wear out, causing equipment efficiency to decrease or even malfunction. irregular spring pressure, poor commutator conditions, contamination, and environmental factors can lead to accelerated. severe voltage surges. If your carbon brushes are wearing out, the tool may cut out during use, signalling complete wear. Of the countless dc motors and generators we. What Causes Carbon Brushes To Wear Out.

From www.slideshare.net

Carbon Brushes Technical Guide What Causes Carbon Brushes To Wear Out common causes of carbon brush wear in dc motors. Of the countless dc motors and generators we have repaired due to carbon brush wear, some of the most. severe voltage surges. over time, carbon brushes will wear out, causing equipment efficiency to decrease or even malfunction. If your carbon brushes are wearing out, the tool may cut. What Causes Carbon Brushes To Wear Out.

From www.electronicscuriosities.com

What is Carbon Brush? Why do we put it in a motor? What Causes Carbon Brushes To Wear Out Of the countless dc motors and generators we have repaired due to carbon brush wear, some of the most. One of the first carbon brushes, this is suitable for use on older, slower machines with. common causes of carbon brush wear in dc motors. severe voltage surges. irregular spring pressure, poor commutator conditions, contamination, and environmental factors. What Causes Carbon Brushes To Wear Out.

From www.theartofdoingstuff.com

How to Replace Carbon Brushes on any motor. The Art of Doing StuffThe What Causes Carbon Brushes To Wear Out If your carbon brushes are wearing out, the tool may cut out during use, signalling complete wear. severe voltage surges. The consequences of worn carbon brushes. excessive sparking may be due to worn brushes, resulting in reduced spring pressure, or due to roughness of the commutator segments. One of the first carbon brushes, this is suitable for use. What Causes Carbon Brushes To Wear Out.